A study to better understand particulate emissions from brakes and tires.

Quantifying non-exhaust particulates, a project led by CRMT

HORECHAP is a project funded by ADEME as part of the AQACIA program, and supported by the EASE laboratory of Gustave Eiffel University, as well as the Laboratory of Physical Chemistry of the Atmosphere of the University of Littoral Côte d'Opale. As a reminder: AQACIA is a program created by ADEME that aims to improve outdoor and indoor air quality.

The goal of this project? To study and quantify non-exhaust particulate emissions from thermal and electric heavy-duty vehicles. The project took place in three main phases. Each of these phases is crucial for achieving the set objectives, as we will see below.

Phase 1: Preparing the ground to ensure the smooth running of the project.

Even before carrying out the on-track tests, UGE and CRMT conducted a long preliminary campaign phase. The objective of this phase was to:

-

Check the proper functioning of the measuring instruments,

-

Validate the data collection and processing procedures,

-

Adjust the experimental protocol under real conditions.

We can therefore ask ourselves: how did CRMT contribute to the preparation of this project? For this, several actions were implemented.

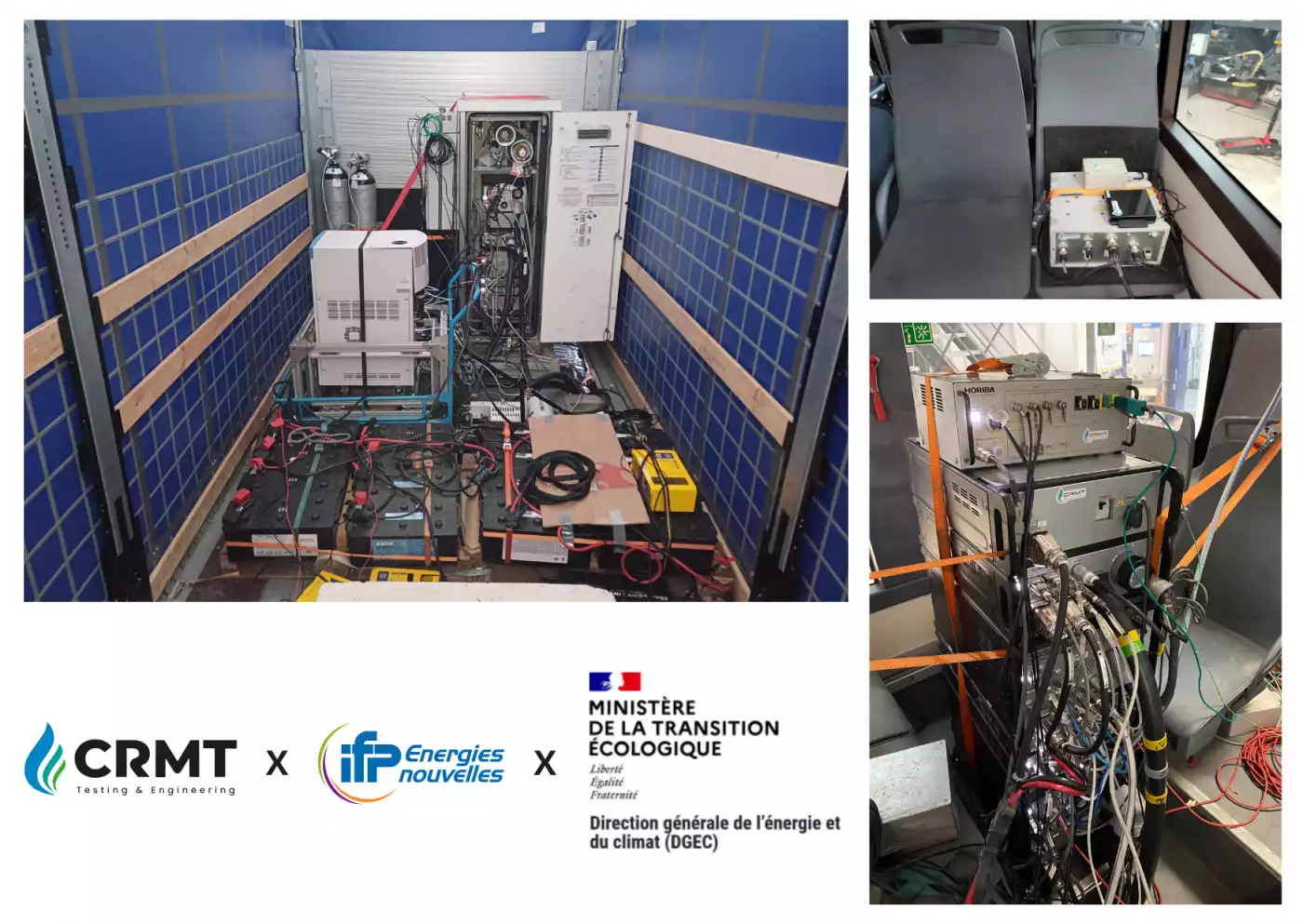

Firstly, CRMT provided UGE with a PEMS (Portable Emission Measurement System) particle analyzer, allowing for continuous measurement of particle concentration.

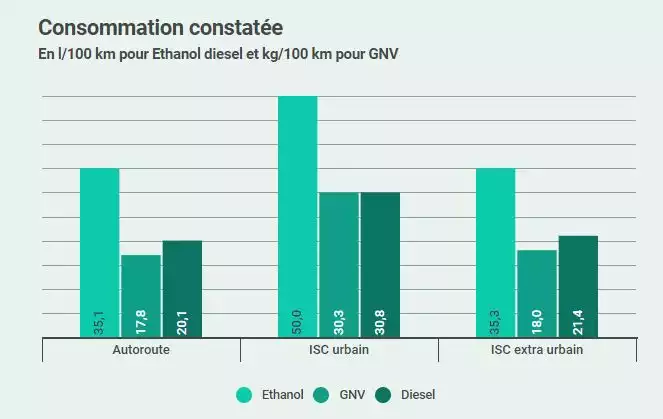

Next, CRMT took charge of defining a route for the tests. This route is based on the ISC (In-Service Conformity) certification cycles, performed with several variations, including an urban, extra-urban, and motorway section. This route distinguished two parts: the urban and extra-urban portions were carried out on a track, and the motorway portion, performed directly on the road. The choice of the track made it possible to avoid any interference related to the presence of other vehicles. In parallel, CRMT also took care of providing two 16-tonne vehicles, one thermal and one electric.

Finally, CRMT designed and manufactured a device for the collection of brake particulates. This device had to comply with safety standards, ensure good thermal management of the system, and guarantee effective collection. The plans were designed to be compatible and easily installable on both vehicles.

Phase 2: On-road data collection is underway!

Following the preparation and innovation phase, UGE and CRMT conducted one month of tests, divided into two periods: the first two weeks for the thermal vehicle, and the last two for the electric vehicle.

CRMT performed several missions during these tests:

-

Installation and technical assistance for setting up the sampling systems and the particle recovery lines, Operational monitoring of the smooth running of the tests.

-

Mobilization of an approved driver within CRMT to guarantee the reproducibility and reliability of the test conditions.

Phase 3: Processing of project data.

After data collection, CRMT calls on its measurement experts to provide raw and processed data to UGE. In addition, objective analyses and interpretation of the results will be delivered to facilitate a better understanding.

These deliverables constitute an essential basis for UGE, allowing for in-depth scientific analyses and contributing to the development of future recommendations regarding the reduction of braking emissions.

Recognized expertise in measuring non-regulated emissions

Faced with the growing challenges linked to air quality, CRMT utilizes its expertise on research and development projects dedicated to emission measurement. Its expertise covers the entire process: from the design of technical solutions to the delivery and analysis of data.

For several years now, the framework agreement established with Gustave Eiffel University has facilitated and strengthened the collaboration between the two entities, particularly within the framework of projects such as CAEFE or HORECHAP.