Number of engines tested: 4

Engine type: CNG

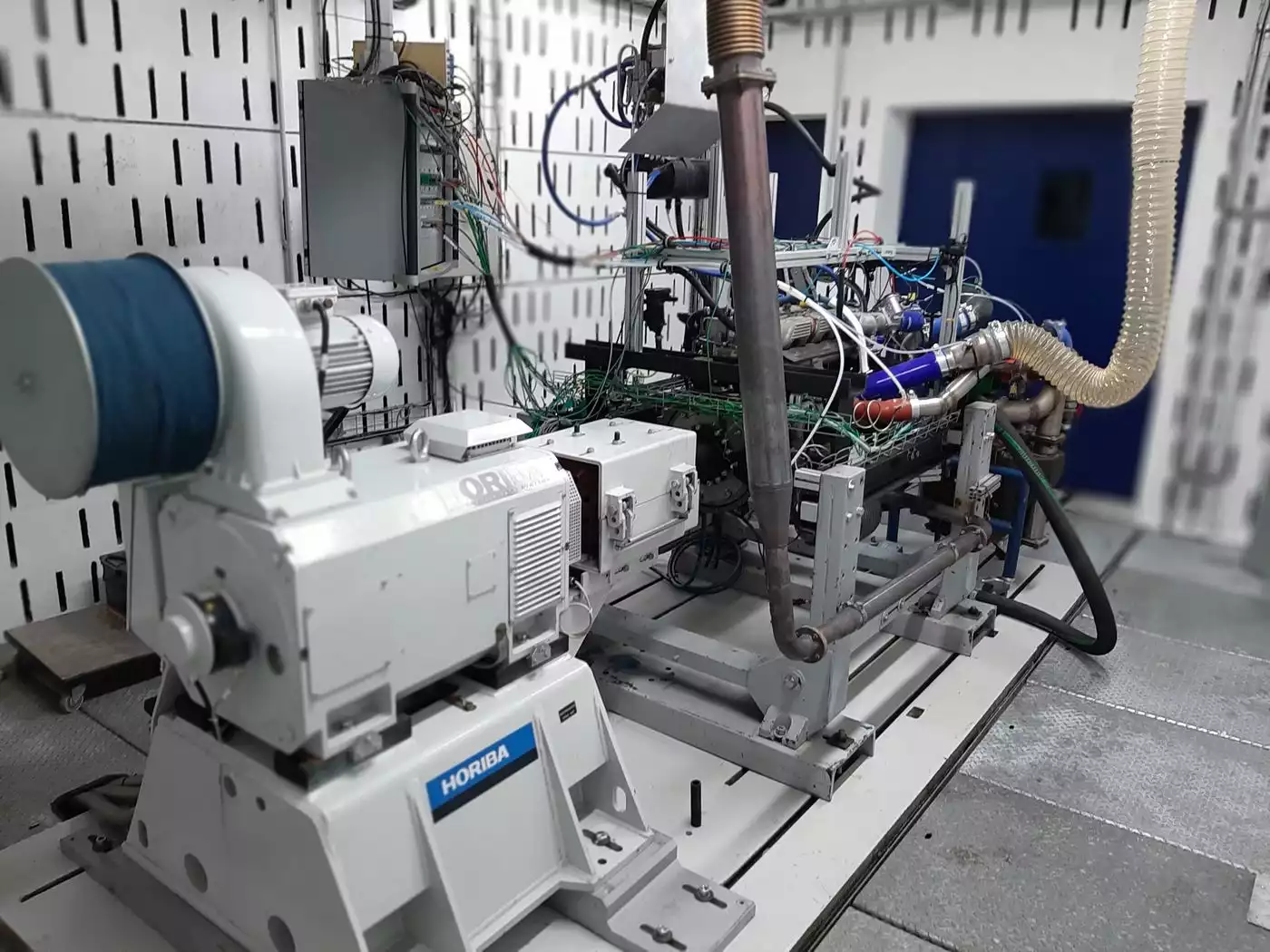

Test type: Bench test, in a test cell designed for performance validation.

Tests enabling certification of remanufactured engines

Context: Control and validate engines through tailored and developed test procedures.

To ensure the proper compliance of newly remanufactured engines intended for heavy-duty applications, CRMT tested four CNG engines in just one week. This project, carried out on behalf of a world-renowned engine manufacturer, mobilized a significant part of our expertise to guarantee reliable and usable data.

How are engine tests carried out for performance validation?

CRMT is involved after CNG engine remanufacturing operations to conduct tests aimed at validating the performance of those reconditioned engines. The remanufacturer, lacking a test cell adapted for gas, relied on our expertise.

Our teams tested four engines in one week, averaging one test every day and a half. Each test includes engine setup, execution of the test, and disassembly.

The process includes the following steps:

- Engine bench installation

The first step is to install the engine on the test bench to ensure optimal and reliable adjustment.

- Warm-up period

A sufficient warm-up time is essential to allow the engine to run under normal operating conditions, as it would in the field. A 10-minute warm-up period is recommended to ensure proper temperature rise.

- Sensor learning.

Carrying out training of the various engine sensors to ensure reliable and usable measurements throughout the tests.

- Determining Maximum Power and Torque

To assess the engine’s maximum power, we begin with a low-load ramp-up. The load is then gradually increased to ensure there are no air leaks that could affect performance. Once maximum speed and load are reached, corresponding data is recorded and analyzed.

- Cool-down period

A sufficient cool-down period is also essential at the end of each test. Engine speed and load are gradually reduced to allow a controlled cooldown before the engine is completely shut down.

These steps are repeated for all engines being tested.

CRMT expertise to ensure your engine performance

As a specialized testing center, our company operates several automated, dedicated test cells, enabling continuous operation 24/7. We are able to test multiple types of fuels, both liquid and gaseous (CNG, H2, E100, and other biofuels). We ensure high-quality standards, even on small series of up to 20 engines. This flexibility allows us to meet the specific needs of our clients efficiently, regardless of engine application type or project complexity.

The multidisciplinary expertise of our team of engineers and engine technicians enables CRMT to carry out various types of tests: endurance, R&D, component testing, engine tuning and calibration, homologation, and as in this case, performance validation.